How PlantBottle® Packaging Can Help Increase Sales

Appeal to customers who make decisions based on sustainability

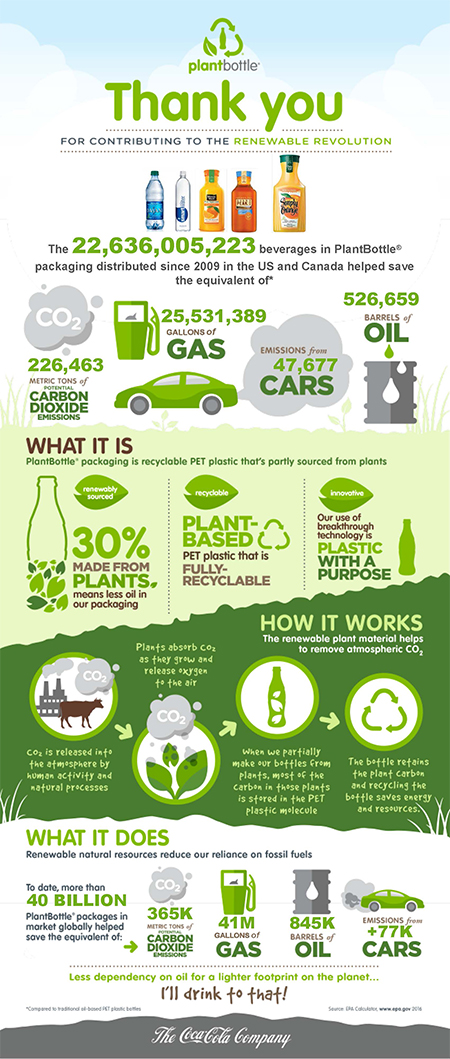

Coca-Cola PlantBottle® packaging results from cutting-edge technology and ground-breaking science. Like conventional PET plastic bottles, it is recyclable. It is made of up to 30% plant-based renewable material and has won numerous awards and accolades since its launch in 2009. Although these are impressive stats, perhaps the most important thing about PlantBottle packaging is how it can help retailers and QSR outlets increase their bottom lines by appealing to consumers who value — and make purchase decisions based on — sustainability.

The challenge for business operators, according to Miki Knutzen, Global Director, PlantBottle Program, is in finding the "sweet spot," where they can increase sustainability-related efforts without losing money. "This is whereCoca-Cola can help," Knutzen says. "Our customers don't have to do a thing except sell Coca-Cola products in PlantBottle packaging."

PlantBottle Technology

Many plastic beverage bottles are made of PET, or polyethylene terephthalate, which is recyclable but not renewable. Conventional PET bottles are made 100% from petroleum, a fossil fuel and nonrenewable resource. PlantBottle packaging is the first PET plastic beverage bottle made partially from renewable plant-based material, which also is recyclable.

Because PlantBottle looks and functions just like traditional PET plastic, it meets consumers' expectations of convenience and safety while reducing the petroleum used and increasing the use of renewable materials, according to Knutzen. "In these ways, PlantBottle packaging is helping to address our shared global environmental challenges," Knutzen says.

Why PlantBottle Packaging

The Coca-Cola Company is the largest PET end user in the world and therefore has a key focus on recyclability, minimizing resources and increasing the use of recycled and renewable materials. "We looked at a variety of options, but we kept coming back to PET plastic because consumers love it," Knutzen says. "PlantBottle technology allows us to make PET plastic from a more sustainable source, and the beauty of it is that it is totally undisruptive to the supply chain."

Where to Find PlantBottle

Today, PlantBottle packaging accounts for 30% of The Company's packaging volume in North America and 7% globally, or 6 billion bottles annually. In the United States, PlantBottle packaging is used in all sizes of DASANI® and smartwater®, 59-oz. carafes of Minute Maid®, Simply® Juice Drinks and Gold Peak® Tea, as well as single-serve sizes of Simply beverages.

The PlantBottle packaging team has worked to clearly, yet quickly and simply, communicate the sustainability-related message. "Since our packaging is the last interaction we have with our consumers, it needs to remind them of our commitment to working toward sustainability," says Nicole Smith, Coca-Cola Sustainability Manager, Customer Collaboration. Many PlantBottle containers can be identified through on-package messages and logos, as well as in-store point-of-sale displays.

"Sustainability can seem very technical and confusing, and there is a fair amount of 'green washing' out there," Smith says. "We try to communicate our sustainability-related messaging so people feel good knowing the beverage and its packaging are beneficial for the entire supply chain."

The Future of PlantBottle Packaging

At the 2015 World Expo in Milan, Coca-Cola unveiled the world's first PET plastic bottle prototype made entirely from plant materials. The packaging looks, functions and recycles like a traditional PET bottle, but when commercialized it will be better for the environment because it will be entirely made from renewable material. Coca-Cola Company Global Research and Development Officer Nancy Quan called the new prototype bottle, "… a pioneering milestone within our Company's packaging portfolio."

It might be seen as a glimpse of what's to come.

"We are working on really dynamic solutions to the challenges before us," Smith says. "It's incredible what the technologies are, how quickly they are moving and how quickly we are shifting to help drive those advancements. We're always looking for that newest technology and innovation that's going to go above and beyond even the goals we have set for ourselves."

Read Related Stories:

The Coca-Cola Sustainability Report Goes Live

Create Greater Customer Connection with Project Ripple